Пользовательские настройки обручального кольца

Возможно, это не столь важное решение, как выбор идеальной пары, но тем не менее важно выбрать обручальное кольцо. Процесс поиска идеального обручального кольца включает в себя множество субъективных решений, но в конечном итоге определяется личным вкусом и вашим бюджетом.

Различные стили настройки и цвета для обручальных колец |

Один

из вариантов-это выбор из каталога или из галереи колец readmade. Для

многих людей не нужно иметь дело с телефонными звонками туда и обратно, а также

с легкостью выбирать кольцо, которое соединяется с ними и продолжает их день.

Кроме того, с многолетним опытом нашей компании в области ювелирного дизайна

они, возможно, придумали что-то настолько уникальное, что вы бы не придумали

сами. Существует множество готовых обручальных колец, доступных "с

полки".” Каталоги ювелирных изделий также могут быть отличной отправной

точкой для генерации идей или даже для поиска чего-то, что действительно

привлекает вас. И конечно, поскольку каждый цветной бриллиант уникален, вы

можете понять, что ваш любимый камень уже установлен в своем идеальном

обручальном кольце.

Обручальное кольцо |

Тем не менее, есть много людей, которые смотрят на задачу поиска и создания

обручального кольца как на один раз в жизни опыт, который нужно смаковать и

наслаждаться. Поэтому, прежде чем вы примете решение, найдите время,

чтобы прочитать это краткое руководство о том, как создаются обручальные

кольца, чтобы ознакомиться с этим процессом.

Первый шаг состоит в том, чтобы найти идеальный фантазийный цвет алмаза в

качестве вашего центрального камня. Как только алмаз выбран, начинается

настоящая работа.

Различные Фантазийные Цветные Бриллианты |

Что-то, что нужно иметь в виду, хотя при выборе цветного алмаза на меньший

бюджет-это концепция “чисто глазу".” Дело в том, что ваша семья и друзья

не ходят с увеличительной лупой, чтобы проверить качество вашего алмаза. Алмаз

может быть тонким, чистым камнем, не обладающим самой высокой степенью чистоты,

поскольку существует множество других факторов, помимо чистоты, которые влияют

на внешний вид алмаза. Если камень чист для глаз, но имеет более низкую степень

чистоты, вы можете сэкономить много денег, не жертвуя много с внешним видом

алмаза.

В случае изготовленного на заказ кольца первостепенное значение имеет

проектирование кольца точно в соответствии со спецификациями заказчика. Тип

металла и его цвет должны быть тщательно продуманы, чтобы дополнить истинный

цвет алмаза. Следовательно, проектная группа нашей компании всегда под рукой,

чтобы предложить любые модификации, необходимые для максимального результата

кольца.

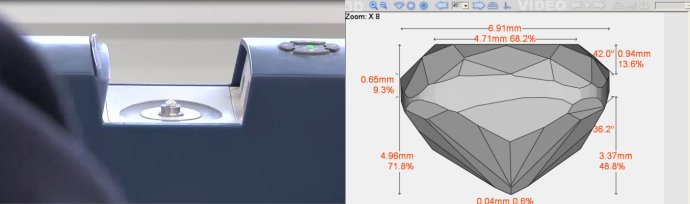

Создание 3D сканирования алмаза с целью создания виртуальной модели |

Затем

Алмаз сканируется, чтобы создать виртуальную 3D-модель камня. Это точно

обеспечивает размеры, структуру и расположение граней бриллианта, позволяя

дизайнерам точно создавать пропорциональные секции драгоценного камня, чтобы он

был максимально эстетичен после сборки.

Создание 3D сканирования алмаза с целью создания виртуальной модели |

Современное программное обеспечение используется для создания виртуальной модели ювелирных изделий. Эта модель обеспечивает точный и пропорциональный дизайн, а также оптимальный комфорт. Готовая виртуальная модель отправляется на печать, и на 3D-принтере генерируется 3D-модель украшения из смолы/воска.

|

Следующий этап включает в себя литье модели, при котором восковая модель прикрепляется к Литейному дереву, где создаются формы для каждого из ювелирных изделий. Каждая секция украшения создается отдельно, так что каждая деталь может быть должным образом подготовлена перед сборкой.

Различные разделы ювелирных изделий до сборки и до и после отливки модели и бриллиантового кольца |

Гипсовая форма создается вокруг воскового дерева посредством литья, и модель высушивается, а воск внутри выжигается, оставляя отрицательную форму украшения. Расплавленное золото или платину заливают в форму колбы. Когда он остынет, гипсовая форма снимается со всего золота или платины, и дерево остается с различными прикрепленными ювелирными секциями, которые удаляются и отправляются на сборку.

Подготовка различных секций ювелирных изделий к сборке |

Отливки вырезаются из дерева, сортируются и очищаются перед тем, как быть спаянными вместе, чтобы создать готовое крепление, которое полируется перед установкой камней. Если есть какие-либо боковые камни, то эти отверстия Теперь просверливаются сеттером.

До и после создания литейного дерева для ювелирных моделей |

На каждом ювелирном изделии начертан тип металла, указывающий, является ли оно

платиновым или 18-каратным золотом. Конечно, на каждом этапе производства

существует множество процессов обеспечения качества, чтобы гарантировать

качество вашего кольца.

Существует много усилий, вложенных в создание идеального дизайна ювелирных

изделий, и Leibish & Co. чувствует, что именно эта инвестиция отличает их

больше всего на свете от большинства других ювелирных компаний. Таким образом,

независимо от того, влюбитесь ли вы в готовое кольцо или решите создать свое

собственное, вы можете быть уверены, что получите продукт высшего качества.

Помните, что самое важное-это ваше удовлетворение и ваше счастье - если это

работает для вас, это все, что имеет значение.